News information

AWK6943 vs MP9943: Compatibility in Printer Power Supply Upgrades

I. Hardware Compatibility: The Foundation for Seamless Printer Power Module Upgrades

1. Complete Compatibility in Packaging and Pin Design

Both the AWK6943 and MP9943 utilize the ultra-compact QFN-8 (3mm×3mm) package, with highly consistent pin layout and function definitions. They can be directly replaced without modifying the printer power PCB design. The key pin function mappings are as follows:

Pin Name | MP9943 Function Description | AWK6943 Function Description | Compatibility Notes for Printer Applications |

FB | Feedback voltage input, sets output voltage | Feedback voltage input, sets output voltage | Direct connection, only need to adjust the voltage divider resistor based on the 1.0V reference |

EN/SYNC (MP9943) / EN (AWK6943) | Enable / synchronization input, supports external clock synchronization | Enable input, supports frequency synchronization (200kHz-2.2MHz) | Compatible with the enable logic control of the printer main control chip |

BST | Bootstrap capacitor connection, drives high-side MOSFET | Bootstrap capacitor connection, drives high-side MOSFET | Continue to use the original 20Ω current-limiting resistor and 0.1μF capacitor configuration |

SW | Switching node output, connected to inductor | Switching node output, connected to inductor | Directly compatible with the 10μH inductor layout of the printer power supply |

PG | Power good indication (open-drain output) | Power good indication (open-drain output) | Connects to the printer status detection circuit, with compatible pull-up resistor |

2. Electrical Parameter Adaptability for Printer Scenarios

l Wide Input Voltage Range and Dynamic Load Support:

The MP9943 supports an input voltage range of 4V-36V, while the AWK6943 supports 3V-36V. Both meet the mainstream 12V/24V power supply requirements of printers. Under a peak output current of 3A, the AWK6943's switching frequency of 410kHz is consistent with that of the MP9943. The original output capacitor design (e.g., 2×22μF ceramic capacitors) can be directly used to ensure stable power supply to dynamic loads such as motors and heating elements during the printing process.

l Equivalent and Enhanced Protection Functions:

Both devices integrate cycle-by-cycle overcurrent protection (OCP), thermal shutdown (TSD), and hiccup mode. However, the AWK6943's thermal shutdown threshold of 165°C (with a 15°C hysteresis) is triggered earlier than the MP9943's 170°C. This enhances reliability in the high-temperature environment near the printer's fusing unit, reducing printing interruptions caused by overheating.

II. Printer-Specific Advantages: From Compatibility to Performance Upgrade

1. Dynamic Load Response: Addressing Peak Power Consumption Challenges

During the printing process, printers experience significant load transients, such as a sudden current surge to 3A when the print head starts. The AWK6943, with its minimum on-time of 40ns (compared to the MP9943's 70ns), can limit output voltage fluctuations to within ±35mV (compared to the MP9943's ±50mV). This ensures stable power supply to the printing data processing chip, preventing issues like character blurring or misalignment caused by voltage fluctuations.

In high-duty-cycle scenarios (e.g., converting 24V input to 20V output for the heating roller), the AWK6943 supports a maximum duty cycle of 98.5% (compared to the MP9943's 95%). This reduces conduction losses by about 4%. During continuous printing, the power module temperature can decrease by 7°C (from 75°C to 68°C), reducing the aging impact of high temperatures on internal printer components.

2. Low-Power Optimization: Standby Energy Saving and Green Printing

l Reduced Standby Power Consumption by 94%:

The MP9943 has a standby current of 0.5mA, while the AWK6943 only has 30μA. For an A4 laser printer that is in standby for an average of 20 hours per day, the annual power consumption can be reduced by about 15 kWh after replacement. This meets international energy-saving certification requirements such as ENERGY STAR, enhancing the environmental competitiveness of printer manufacturers.

l Improved Light-Load Efficiency by 8-10%:

In sleep mode, printers typically have a load current of 10-50mA. The AWK6943's PFM mode automatically skips pulses, achieving a light-load efficiency of over 90%, which is higher than that of the MP9943. This reduces energy waste, especially suitable for commercial printers that frequently enter sleep and wake-up cycles.

3. Enhanced Reliability: Adapting to Complex Printer Operating Environments

l AEC-Q100 Certification and Wide Temperature Performance:

The AWK6943 has passed the automotive-grade AEC-Q100 certification and supports a junction temperature range of -40°C to 125°C. In the high-temperature environment caused by long-term printer operation, it offers more stable performance compared to the MP9943, which does not explicitly have an automotive-grade qualification. This reduces power supply failures caused by temperature fluctuations.

l EMI Suppression and Anti-Interference Design:

The AWK6943's EMI radiation is 5dB lower than that of the MP9943, reducing interference with the printer's wireless modules (e.g., Wi-Fi, Bluetooth) and preventing data transmission interruptions during printing. Its optimized switching node design also reduces noise impact on the print head drive circuit, improving the consistency of print quality.

4. Simplified Design and Cost Optimization

l Peripheral Component Reuse Rate Over 90%:

Commonly used components in printer power supplies, such as 10μH inductors and 22μF output capacitors, can be directly reused. The AWK6943's built-in compensation circuit eliminates the need for additional RC networks, reducing the number of components by 2-3 compared to the MP9943 solution and lowering BOM costs by about 5%.

l Flexible UVLO Threshold Configuration:

Printer power supplies may experience voltage drops due to power grid fluctuations (e.g., 12V input momentarily dropping to 10V during startup). The AWK6943 can set the UVLO rising threshold to 4V through resistor voltage division on the EN pin (compared to the MP9943's fixed 3.5V). This triggers protection earlier, avoiding interruptions in printing tasks caused by undervoltage.

III. Replacement Design Considerations and Case Studies

1. Key Parameter Adjustment Guidelines

l Output Voltage Calculation:

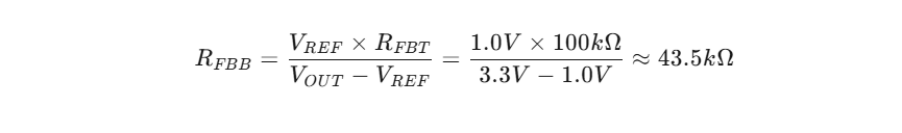

If the original MP9943 solution outputs 3.3V (R7=41.2kΩ, R8=13kΩ), when replacing with the AWK6943, the voltage divider resistor needs to be recalculated due to the 1.0V V_FB reference:

It is recommended to use a 43kΩ±1% precision resistor to ensure output voltage accuracy.

l Inductor and Capacitor Verification:

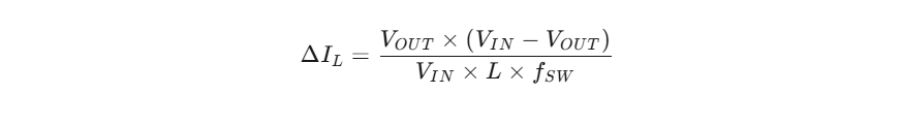

When using a 10μH inductor, the ripple current needs to be verified:

For example, with a 12V input and 5V output, ΔI_L≈0.9A. An inductor with a rated current of ≥3.45A (I_LOAD + ΔI_L/2) should be selected to prevent magnetic saturation.

2. Actual Application Case Comparison

A certain model of multifunction printer (MFP) originally used the MP9943 solution:

l Input 12V, output 5V/3A, printing efficiency 88%, standby power consumption 1.2mW, power module temperature 75°C after continuous printing for 1 hour.

After replacing with the AWK6943:

l Printing efficiency increased to 92%, temperature reduced to 68°C under the same load;

l Standby power consumption reduced to 0.072mW, saving about 15 kWh per year;

About Mandu Technology

Shenzhen Mandu Technology Co., Ltd. has steadfastly centered its operations on the distribution of high-performance, high-quality, and highly reliable integrated circuit products. Its portfolio encompasses memory chips, differential crystal oscillators, and MCU microcontrollers, while progressively integrating analog signal chain products. The company prides itself on delivering comprehensive and cost-effective solutions to its customers. Its products find applications across a broad spectrum of industries, including but not limited to network communication, industrial control, robotics, medical equipment, personal health, and numerous other fields.

Business: sales@manduic.com

Website: www.manduic.com

Sales: +86 150-1290-5940

Product Center

News information

- Analogwin AWL5963KAR-18 Industrial-Grade Power Solution

- W25Q64JVSSIQ — A High-Speed, Reliable, and Low-Power 64Mbit SPI NOR Flash

- YUNTU Automotive-Grade MCU Selection Guide for In-Vehicle Gateways

- YEESTOR SGM8103J pMLC Automotive Electronic Storage Solution

- Epson Q13FC13500049: The Timing Foundation for Wearable Device

contact us

Telephone: +86-150-1290-5940

Mobile phone: +86-150-1290-5940

Mailbox: sales@manduic.com

Address: Room 618, 6th Floor, Derun Building, No. 366 Chaofeng Road, Fenghuang Street, Guangming District, Shenzhen, China